Views: 0 Author: Site Editor Publish Time: 2025-05-13 Origin: Site

Polyester staple fiber (PSF) stands as a cornerstone in the textile industry, offering versatility and durability across a myriad of applications. The machinery involved in producing PSF plays a pivotal role in defining both the quality and efficiency of the fiber production process. Understanding the price of polyester staple fiber making machines is essential for manufacturers aiming to optimize their production capabilities while maintaining cost-effectiveness. This analysis delves into the multifaceted factors influencing the pricing of these machines, providing a comprehensive perspective for stakeholders in the textile sector.Investing in advanced polyester staple fiber production machinery can significantly enhance operational efficiency and product quality, setting manufacturers apart in a competitive market.

The production of polyester staple fiber is a sophisticated process that blends chemical engineering with advanced manufacturing techniques. It begins with the polymerization of monomers to create the polyester polymer, followed by fiber formation through spinning, drawing, crimping, and cutting. Each stage requires specialized machinery designed to ensure optimal fiber properties such as strength, elasticity, and dye affinity.

Technological advancements have propelled the development of machinery that not only improves efficiency but also enhances fiber quality. Modern PSF making machines are equipped with automation systems, precision controls, and energy-efficient components. These features contribute to higher production rates, consistent product quality, and reduced operational costs. Consequently, manufacturers aiming to remain competitive must consider investing in advanced machinery to meet evolving market demands.

A comprehensive understanding of the components within polyester staple fiber making machines provides valuable insight into their pricing. These machines comprise several critical units, each contributing to the overall functionality and efficiency of the production line.

The polymerization unit synthesizes the polyester polymer through a chemical reaction involving terephthalic acid and ethylene glycol. Precision in temperature and pressure control within this unit is vital for producing a polymer with the desired molecular weight and viscosity. High-end polymerization units feature advanced control systems and catalysts that enhance reaction efficiency, although they increase the initial investment required.

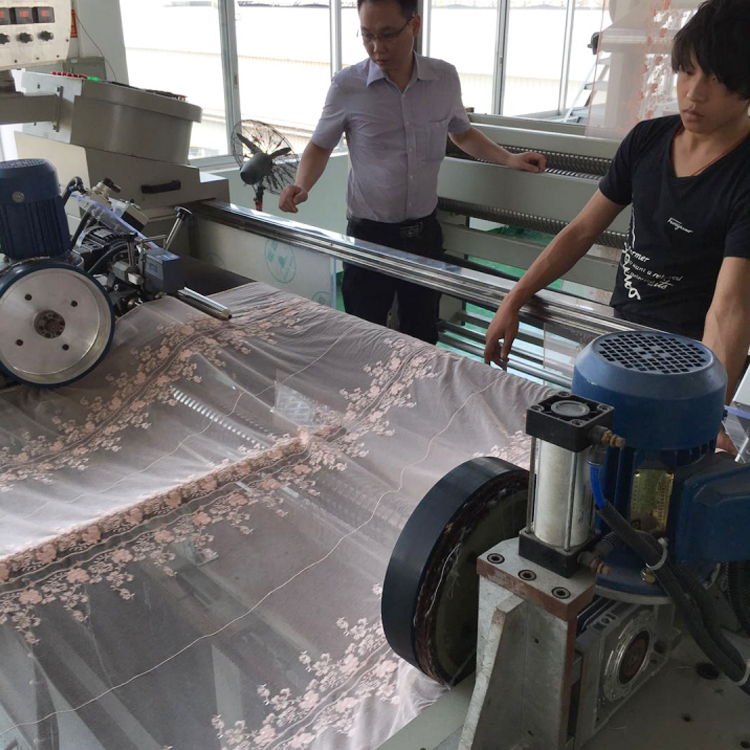

In this stage, the molten polyester is extruded through spinnerets to form continuous filaments. The design and quality of the spinnerets affect the filament diameter and uniformity. State-of-the-art spinning systems incorporate computerized controls that adjust extrusion parameters in real time, ensuring consistent fiber quality. These technological enhancements contribute to higher machine costs but offer long-term benefits in production efficiency.

Following extrusion, the fibers undergo drawing to align the polymer chains, enhancing tensile strength. The crimping process imparts a three-dimensional structure to the fibers, improving bulkiness and texture. Machinery equipped with advanced drawing and crimping capabilities can produce fibers tailored to specific applications. These specialized features influence the overall price of the machinery.

The cutting system segments the continuous fibers into staple lengths, which are then ready for packaging. Precision in cutting ensures uniform fiber lengths, crucial for downstream textile processes. Automated packaging systems streamline the handling of fibers, reducing labor costs and protecting fiber integrity. Investment in high-quality cutting and packaging equipment enhances operational efficiency but contributes to the overall machinery cost.

The price of polyester staple fiber making machines varies significantly based on multiple factors. Manufacturers must consider these elements to make informed purchasing decisions that align with their operational and financial objectives.

Machines equipped with the latest technological innovations command higher prices due to the enhanced capabilities they offer. Features such as automation, real-time monitoring, and energy-efficient operations increase productivity and reduce long-term operational costs. Investing in modern technology provides a competitive edge but requires a higher initial expenditure.

The production capacity of the machinery directly influences its price. Machines designed for higher output volumes incorporate robust components and advanced systems to handle increased workloads. Although these machines involve higher costs, they enable manufacturers to meet large-scale production demands and capitalize on economies of scale.

Machines constructed with high-quality materials offer enhanced durability and longevity. Components resistant to wear and corrosion reduce maintenance needs and operational downtime. While initial costs are higher for durable machinery, the long-term savings and reliability often justify the investment.

Advanced automation minimizes human intervention, reducing the likelihood of errors and increasing efficiency. Integrated control systems allow for precise adjustments to production parameters, enhancing fiber quality. The inclusion of sophisticated automation features raises the machinery's price but delivers significant benefits in consistency and productivity.

Established manufacturers with a reputation for quality and reliability often price their machines higher. Brands like VIROCK Textile Machinery Co., Ltd. offer extensive experience, professional technical teams, and high-performance CNC machining equipment. Their commitment to innovation and customer feedback integration adds value to their machinery, justifying the cost.

Investing in high-end polyester staple fiber making machines involves substantial capital but offers significant benefits that can justify the expense. Advanced machinery enhances product quality, operational efficiency, and sustainability, leading to improved profitability over time. A detailed cost-benefit analysis helps manufacturers assess the long-term advantages of such investments against the initial costs.

For instance, machines with energy-efficient systems reduce electricity consumption, lowering operational expenses. Automation decreases labor costs and minimizes errors, resulting in consistent product quality and reduced waste. Over several years, these savings can offset the higher purchase price of advanced machinery.

The global market for polyester staple fiber making machines is influenced by factors such as raw material prices, technological developments, and geopolitical dynamics. Manufacturers need to stay informed about market trends to anticipate price fluctuations and make strategic purchasing decisions. Collaborating with established suppliers can provide insights into market conditions and offer opportunities for favorable pricing or financing options.

Analyzing pricing models from leading manufacturers provides practical insights into the cost structures of PSF making machines. For example, VIROCK Textile Machinery Co., Ltd. offers machines that integrate advanced technology and high-quality components. While their equipment may have a higher initial price, the long-term benefits in efficiency and product quality often result in a favorable return on investment.

These case studies highlight the correlation between machine capabilities and pricing, assisting potential buyers in evaluating their options. Manufacturers can compare features, assess the value provided, and align their choices with their production goals and budget constraints.

When purchasing a PSF making machine, manufacturers should consider several practical aspects to ensure a wise investment. Evaluating the machine's features relative to production needs, assessing the supplier's after-sales support, and inspecting the quality of components are crucial steps. Exploring financing options and negotiating terms can alleviate financial burdens and facilitate a smoother acquisition process.

Engaging with suppliers who offer comprehensive services enhances the purchasing experience. Companies like VIROCK provide equipment installation guidance, after-sales services, and a wide range of spare parts and accessories, delivering a complete solution to customers.

Manufacturers should also consider the machine's scalability to accommodate future growth, ensuring that the investment remains viable as production demands evolve. By conducting thorough research and due diligence, buyers can select machinery that offers the best balance of cost and capabilities.

Understanding the pricing of polyester staple fiber making machines involves a comprehensive analysis of multiple factors, including technological features, production capacity, and market dynamics. Manufacturers must carefully evaluate their specific needs and long-term objectives to make informed purchasing decisions. Investing in advanced machinery can offer significant returns through enhanced efficiency, product quality, and competitive advantage in the textile industry. By considering the insights provided in this analysis, stakeholders can navigate the complexities of machinery pricing and optimize their investments accordingly.

1. What are the main factors affecting the price of polyester staple fiber making machines?

The price is influenced by technological advancements, production capacity, material quality, automation systems, and the reputation of the manufacturer. Advanced features and higher capacities generally lead to higher costs.

2. How does automation impact the cost and efficiency of PSF production machinery?

Automation enhances operational efficiency by reducing manual intervention, minimizing errors, and increasing production speed. While it raises the initial cost of the machinery, it leads to long-term savings and productivity gains.

3. Why is investing in high-quality components important for PSF machines?

High-quality components ensure durability, consistent performance, and lower maintenance costs. They contribute to the machine's longevity and reduce downtime, which is critical for continuous production environments.

4. Can purchasing from reputable manufacturers like VIROCK Textile Machinery Co., Ltd. provide advantages?

Yes, established manufacturers offer reliable machinery, professional after-sales support, and adherence to international standards, ensuring optimal performance and compliance with industry regulations.

5. What should manufacturers consider when performing a cost-benefit analysis for PSF machinery?

They should assess the initial investment against long-term benefits such as improved efficiency, product quality, energy savings, and potential revenue increases. Evaluating operational costs and maintenance requirements is also essential.

6. How do global market trends affect the pricing of PSF making machines?

Market trends influence raw material costs, demand for polyester fibers, and technological advancements, which in turn affect machinery prices. Staying informed about these trends helps manufacturers make strategic purchasing decisions.

7. What role does production capacity play in determining the price of PSF machinery?

Machinery designed for higher production capacities is built with robust components and advanced systems to manage increased workloads, resulting in higher prices. The investment can be justified by the ability to meet large-scale demand and achieve economies of scale.